Melamine Moulding Compound (Granule form, compression grade)

Melamine Moulding Compound

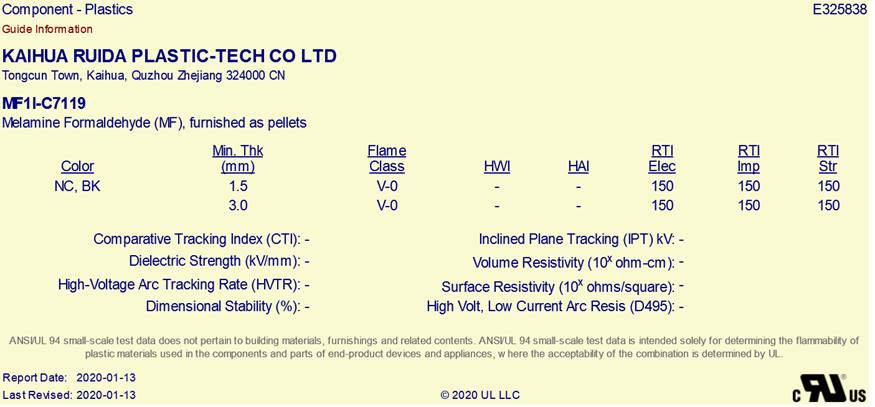

RuiDa’s Melamine Formaldehyde Moulding Compound (MMC) are based on melamine formaldehyde resin and takes cellulose, minerals as the filling, together with both lubricant, hardener and pigment, etc.

l Product Properties

1. After molding, the surface should be flat, shinny and smooth, no bubbles or crack,

color and foreign material achieves standard.

2. High Strength, Anti-scratch, Anti-PH, Anti-heat, No Poison,

Good Shinning, No Color changing with long term use, Easy-molding.

3. 100% melamine, food grade

4. Color difference: Delta E <0.6

l Product classification

1, General grade, most used for pressing the melamine tableware, as well as flower pots, toys, etc., with low price, excellent product performance, complete color.

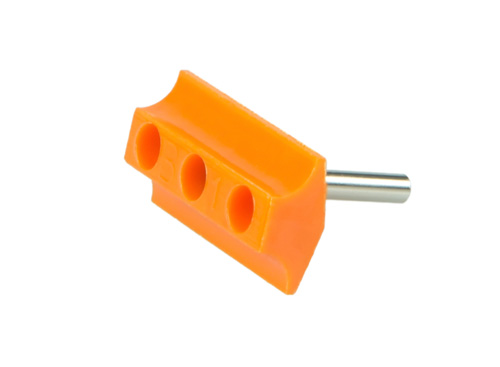

2, Electrical grade, improve the electrical performance and stability of the material, used for pressing electrical switch panel, lamp holder, lamp holder, etc.

3, Enhanced grade, improve the transparency of the material, the selection of high whiteness wood pulp, provide the whiteness of the material, gloss, suitable for pressing a variety of buttons, pearls, jade porcelain tableware, cosmetics bottle caps and so on.

l Color difference:

Color standard | L | a | b |

87.25 | 0.45 | -0.25 | |

Acceptance range | 0~0.6 | ±0.2 | ±0.3 |

△E:≤0.6 | |||

l Production Specification

Number | Test Items | Index | Test Result |

1 | Fluidity, mm | 110-140 | 115 |

2 | Volatile Content % ≤ | 5.00 | 3.03 |

3 | Exterior | Qualified | |

4 | Boiling Water-proof | Qualified | |

5 | Flexural Strength, Mpa ≥ | 80 | 87 |

6 | Impact Strength, KJ/㎡ ≥ | 1.7 | 1.9 |

7 | Temperature of hot distortion, ℃ ≥ | 115 | 150 |

8 | Water absorption(Cold water) mg ≤ | 50 | 25 |

9 | Molding Shrinkage, % | 0.5-1.0 | 0.55 |

10 | Dielectric resistance after 24h in water, MΩ ≥ | 104 | 2.5*105 |

11 | Dielectric Strength, MV/m ≥ | 5.0 | 9.5 |

l Company view

Packaging: Paper bag with wet proof inner plastic. 25kg/bag

Storage: Kept in airy, dry and cool room.

Storage period: six months from the manufacturing date.