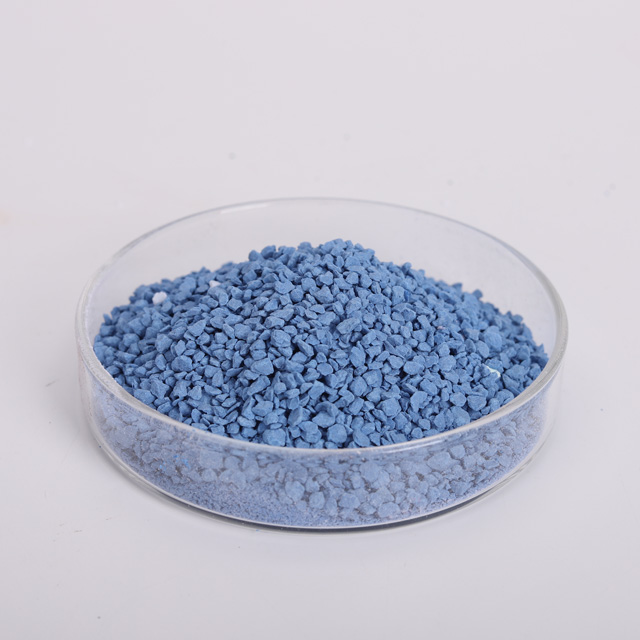

Urea Moulding Compound (Granule form, injection grade)

Urea Moulding Compound

RuiDa’s Urea Moulding Compound(UMC) are based on urea formaldehyde resin and takes cellulose, mineral as the filling, together with both lubricant, hardener and pigment, etc.

l Application: It is suitable for the injection molding to manufacture household appliances, low-voltage appliances, instrument insulation structure and mechanical parts.

l Color: Almost any color is available, we have strong team for color matching, can satisfy all your requirement.

l Product Properties

1. After molding, the surface should be flat, shinny and smooth, no bubbles or crack,

color and foreign material achieves standard.

2. Color difference: Delta E <0.6

l Product classification

The injection material produced by our company solves the problems of product black marks, color shifting and so on. Under the condition of stable product color difference value, according to different customers, different products, different production conditions, targeted optimization of injection performance, to provide each customer with the most appropriate materials.

This product is mainly used for pressing electrical parts, air conditioning parts, and a variety of insulation, temperature resistance requirements of the product, material particles uniform, suitable for automatic feeding process.

Color difference:

Color standard | L | a | b |

87.25 | 0.45 | -0.22 | |

Acceptance range | 0~0.6 | ±0.2 | ±0.3 |

△E:≤0.8 | |||

Production Specification

Number | Test Items | Index | Test Result |

1 | Fluidity, mm | 110-140 | 125 |

2 | Volatile Content % ≤ | 5.00 | 3.45 |

3 | Exterior | Qualified | |

4 | Boiling Water-proof | Qualified | |

5 | Flexural Strength, Mpa ≥ | 80 | 85 |

6 | Impact Strength, KJ/㎡ ≥ | 1.7 | 1.8 |

7 | Temperature of hot distortion, ℃ ≥ | 115 | 125 |

8 | Water absorption(Cold water) mg ≤ | 100 | 65 |

9 | Molding Shrinkage, % | 0.5-1.0 | 0.82 |

10 | Dielectric resistance after 24h in water, MΩ ≥ | 104 | 2.6*105 |

11 | Dielectric Strength, MV/m ≥ | 7.0 | 10 |

l Injection Condition

Mould temperature: 120-130 °

Charging barrel temperature: front: about 80° back: about 70°

Injection pressure: 100-130 Mpa

Speed: 45%

Dwell time: 3-5 second

Curing time: 7 second/mm

Our Advantage

1. More than 36 years experience in this field.

2. Special in producing granular injection grade urea molding compound.

3. Big production capacity, 20 tons/day, small order is acceptable.