Urea Moulding Compound (Granule form, compression grade)

Urea Moulding Compound

RuiDa’s Urea Moulding Compound(UMC) are based on urea formaldehyde resin and takes cellulose, mineral as the filling, together with both lubricant, hardener and pigment, etc.

l Application: It is suitable for the pressing molding to manufacture urea-formaldehyde toilet cover, cosmetic bottle cap, household appliances, low-voltage appliances, instrument insulation structure and mechanical parts.

l Color: Almost any color is available, we have strong team for color matching, can satisfy all your requirement.

l Product Properties

1. After molding, the surface should be flat, shinny and smooth, no bubbles or crack,

color and foreign material achieves standard.

2. Color difference: Delta E<0.6

l Product classification

1, General grade, most used for pressing the melamine tableware, as well as flower pots, toys, etc., with low price, excellent product performance, various color.

2, Sanitaryware grade, specially used to make toilet seat cover, strictly control the product black spots, liquidity, improve the shrinkage rate of the material, dimensional stability, etc.

3, Electrical grade, improve the electrical properties and dimensional stability of the material, strictly control the product black spots and fine powder content, mostly used for pressing electrical switch panel, lamp holder, lamp holder, uniform product particles, suitable for automatic feeding process.

4, Enhanced grade, Improve the material can be painted, electroplated, suitable for pressing a variety of cosmetics bottle caps.

1. Appearance cleanliness:

Item | A class | B class |

Black spot | No visible spot | ф0.4mm≤3 |

Impurity | ||

Dark spot | ф0.4mm≤2 | ф0.6mm≤2 |

White spot | 0 | ф0.4mm≤2 |

Transparent spot | 0 | ф1.0mm≤2 |

2. Color difference:

Color standard | L | a | b |

87.25 | 0.45 | -0.25 | |

Acceptance range | 0~0.6 | ±0.2 | ±0.3 |

△E:≤0.6 | |||

3. Other outgoing quality inspection items:

Inspect items | A class | B class |

Volatile % | ≤4.0% | |

Fluidity mm | 110-115mm | 100-120mm |

Curing time s | 53~55s | |

Production Specification

Number | Test Items | Index | Test Result |

1 | Fluidity, mm | 100-120 | 115 |

2 | Volatile Content % ≤ | 5.00 | 4.00 |

3 | Exterior | Qualified | |

4 | Boiling Water-proof | Qualified | |

5 | Flexural Strength, Mpa ≥ | 80 | 87 |

6 | Impact Strength, KJ/㎡ ≥ | 1.7 | 1.88 |

7 | Temperature of hot distortion, ℃ ≥ | 115 | 125 |

8 | Water absorption(Cold water) mg ≤ | 100 | 32 |

9 | Molding Shrinkage, % | 0.5-1.0 | 0.55 |

10 | Dielectric resistance after 24h in water, MΩ ≥ | 104 | 2.6 x 105 |

11 | Dielectric Strength, MV/m ≥ | 7.0 | 10 |

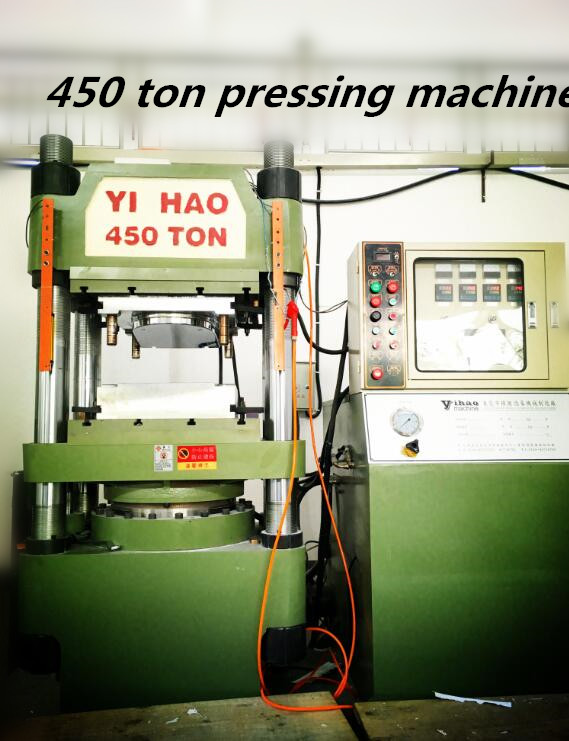

· Quality control

Warehouse and production shop

1x20GP can load 20-23 tons, 800-920 bags, without pallet.

Delivery period: within 10 days.

Packaging: Kraft bag with wet proof inner bag. 25kgs/bag

Storage period: 6 months kept in cool warehouse.

Hot Tags: urea molding compound, China, manufacturers, supplier, factory, price